3D Printed CNC Router Machine

Project Overview

The 3D Printed CNC Router Machine is an innovative and cost-effective solution designed for hobbyists, makers, and small businesses to enter the world of computer numerical control (CNC) machining. This project aims to leverage 3D printing technology to create an accessible and customizable CNC router, capable of various tasks such as engraving, cutting, and milling on a variety of materials.

Components

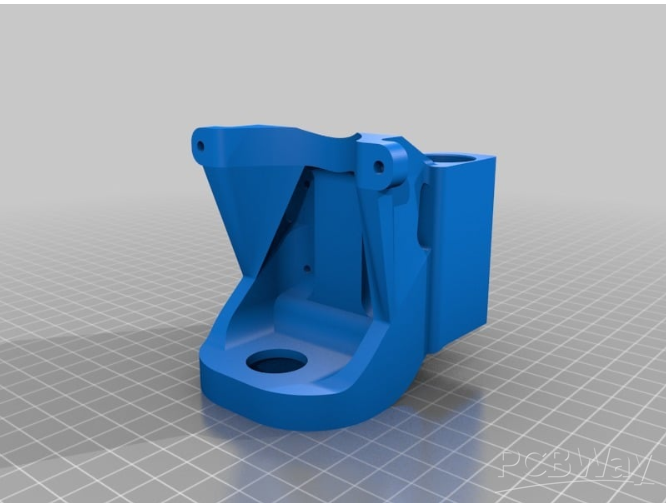

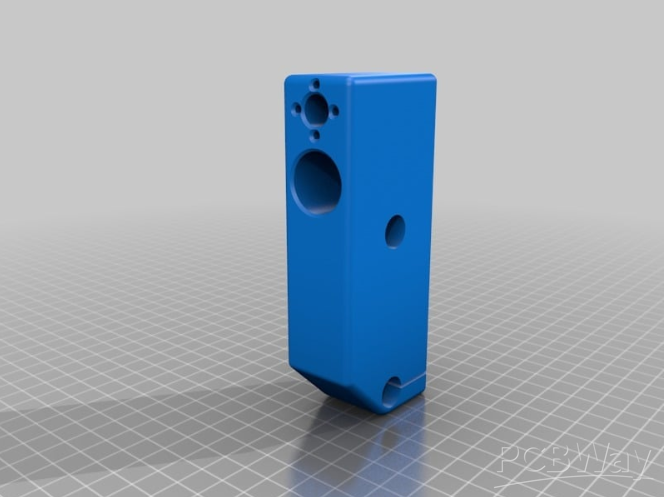

3D Printed Parts: These parts form the structure and frame of the machine, making it lightweight, adaptable, and easy to assemble.

Nema 17 Stepper Motors (4x): These motors provide precise control over the movement of the router in both X and Y axes.

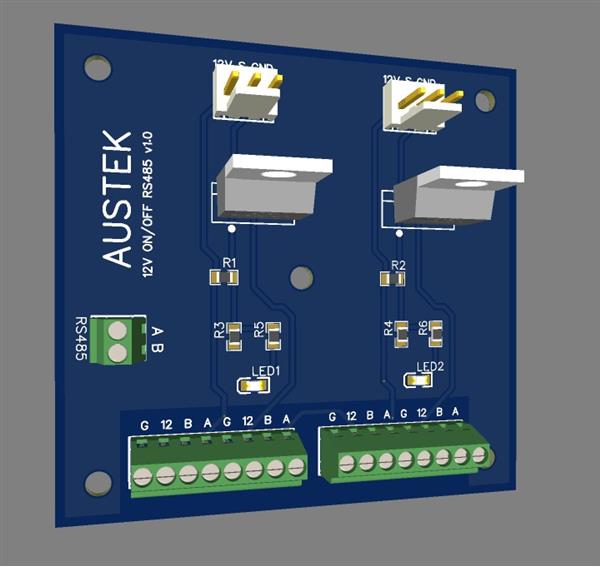

GRBL Control Board: The GRBL control board interprets G-code commands and controls the stepper motors to move the router accurately.

A4988 Drivers (4x): These drivers are responsible for regulating the current supplied to the stepper motors, ensuring smooth and precise movement.

Lead Screws (4x): Lead screws convert the rotational motion of the stepper motors into linear motion, allowing the router to move precisely along the X and Y axes.

Stainless Steel Rods (8x): These rods provide stability and rigidity to the machine's structure.

Linear Bearings (8x): Linear bearings allow smooth and frictionless movement along the linear rods.

300W Router: The router is the cutting or engraving tool that is mounted on the CNC machine, allowing it to perform various tasks on materials like wood, plastic, or aluminum.

COMPLETE STL FILE LINK:https://drive.google.com/file/d/14FzPU_GkegJpEQfGti5Iu1EYdt6M2XKb/view?usp=sharing

How It Works

1. G-code Generation: Users design their desired 2D or 3D models using computer-aided design (CAD) software and convert them into G-code, which contains instructions for the CNC machine.

2. G-code Upload: The generated G-code is uploaded to the GRBL control board via a computer or microcontroller.

3. Motor Control: The GRBL board interprets the G-code commands and sends corresponding signals to the A4988 drivers, which control the Nema 17 stepper motors. These motors drive the router along the X and Y axes with high precision.

4. Z-axis Movement: The router's Z-axis can be adjusted manually to set the desired depth for cutting or engraving.

5. Material Setup: Users secure the workpiece on the CNC machine's bed.

6. Operation Start: The user initiates the CNC machine, and it follows the G-code instructions, moving the router precisely to cut or engrave the material as per the design.

Benefits

- Affordable and accessible CNC machining for hobbyists and small businesses.

- Customizable and adaptable design.

- Enables precise and intricate cutting, milling, and engraving.

- Utilizes 3D printed components for easy replication.

- Versatile for various materials and applications.

- Comments(0)

- Likes(6)